It's no secret that the t-shirt business can be a dirty business - especially for the environment! Here at The Shack, we have always been conscientious of our waste and what happens to our spoilage, so we are proud to share with you, our Shackers, how we do our part to have the smallest environmental impact possible - both before and after production.

3 THINGS WE DO TO REDUCE WASTE IN OUR PRODUCTION ROOM

1. OUR SCRAP BECOMES YOUR CARPETING! - Every design we print has to be tested first for accuracy. Every. Single. Design. That means we use a lot of t-shirts for "practice" and those shirts never go out the door to our customers. If they don't go out the door, where do they go? We accumulate our test prints until we have a substantial amount of them. We then box them up and ship them to a homeless shelter in Oklahoma City. Why this particular homeless shelter? Because we have personally volunteered there, and have assisted them in going through unwearable clothing. We've helped them load this clothing into a van and transported it to a carpet manufacturer where the scrap is weighed and measured. The homeless shelter is paid by the pound for the scrap, and the carpet manufacturer shreds the shirts and makes carpeting out of it! It's a win for everyone!

2. WE USE BIODEGRADABLE CHEMICALS! - Every screen we use has to be stripped down naked so it can be used again in our darkroom. Where does all of that ink, emulsion, and gunk go once we remove it from the screen? Down the drain? NO WAY! Not here! First, of all, we use a totally biodegradable reclaim system called EasiWay. It's better for our screens, better for our staff, and better for our earth!

3. WE FILTER OUR WASTE TO SEND CLEAN WATER BACK INTO THE SYSTEM! - As if it's not enough that we use biodegradable chemicals for our reclaim room, we go even further by adding a filtration system by Blackline. This system filters the dirty water from our screens THREE TIMES before sending clean water back into the system! Now that's responsible cleaning!

HOW ALLMADE TRIBLEND TEES PLAY A PART IN OUR ECO-FRIENDLY GAME

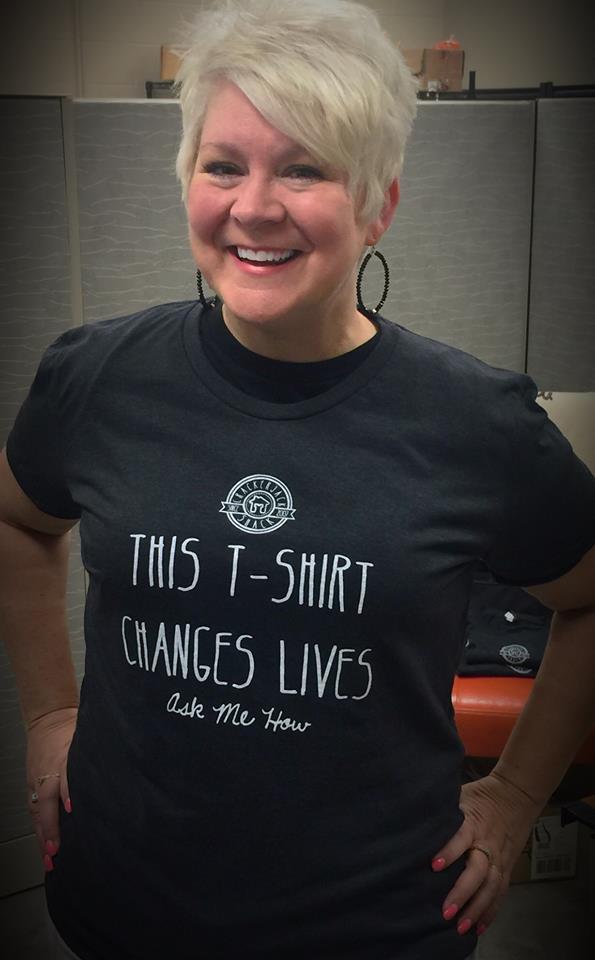

Allmade t-shirts are different. The fabric is different, the factory is different, the entire concept is different....and WONDERFUL! We've been watching the growth of this emerging brand for quite some time now, and in the late summer of 2018, our staff made a unanimous commitment to fully promote it. Here's how The Shack and Allmade are changing lives one t-shirt at a time!

THE FABRIC

Allmade considers 3 things when it comes to fabric - how the fibers are cultivated or manufactured, how they are processed, and how much transport is required. Allmade tri-blends contain organic cotton, TENCEL™ Modal (from trees!), and recycled plastic bottles that are turned into polyester.

ALLMADE COTTON VS. REGULAR COTTON

Allmade only uses USA GROWN 100% organic cotton in its triblend t-shirts - meaning it is free of synthetic fertilizers, pesticides and other chemicals that harm the environment.

Did you know that Non-organic cotton is known as the world's dirtiest crop? Because of synthetic fertilizers, pesticides, insecticides, and chemical defoliants used to grow and harvest this cotton, it is extremely harmful to the environment! Additionally, in order to make non-organic cotton pure white, chlorine bleach and optical brighteners must be used.

Allmade's organic cotton is different! The dyes used to color the fabric isn't harmful to the environment, and to get pure white, they use oxygen bleach! That means less processing, fewer additives, and a softer, more luxurious shirt to wear than non-organic cotton!

ALLMADE POLYESTER VS. REGULAR POLYESTER

The polyester in Allmade tri-blends is created from recycled plastic water bottles. Plastic bottles are diverted from landfills from across the United States and turned into recycled polyester yarn. There are 6 plastic bottles in every Allmade tri-blend. That translates into a bunch of plastic bottles not ending up in landfills! Not only are they avoiding new polyester from being created, with all harmful side-effects, the use of recycled PET bottles reduces water use by 90% and uses 40% less energy. (Courtesy of Allmade)

Regular polyester is made from a combination of...well...from our friends at Wikipedia...Polyester is a synthetic polymer made of purified terephthalic acid (PTA) or its dimethyl ester dimethyl terephthalate (DMT) and monoethylene glycol (MEG). With 18% market share of all plastic materials produced, it ranges third after polyethylene (33.5%) and polypropylene (19.5%).

Yeah...as you can guess...recycling plastic bottles is a much better way to get polyester than manufacturing a concoction of petroleum and other chemicals!

THE THIRD INGREDIENT IN TRIBLEND TEES - ALLMADE TENCEL™ MODAL VS. RAYON

Most triblend t-shirts from other brands use rayon as the third ingredient. Allmade doesn't. TENCEL™ Modal is extremely soft, but more importantly, it is much more environmentally friendly than rayon. TENCEL™ Modal is a man-made fiber made from beech trees. It is certified by FSC, a global not-for-profit organization that sets the standards for what is a responsibly managed forest, both environmentally and socially. Interestingly, the beech tree naturally regenerates without the need for artificial irrigation. Beech wood forests are completely natural and they are a sustainable source for material!

Rayon, however, is frequently derived from virgin and unmanaged forests. It requires much harsher chemicals to process, and that contributes to water and air pollution. Manufacturing rayon is extremely damaging to the environment!

ALLMADE KEEPS THE TRANSPORTATION LOOP TIGHT

Did you know that the typical garment travels 16,000 miles (on average) from source to retail store? SIXTEEN THOUSAND MILES! Think of the resources used - gas, oil, electricity, water, manpower, etc. - to transport literally millions of garments that distance. Frankly, it's excessive. We love that Allmade keeps the transportation loop tight! Most of the production of Allmade happens here in the U.S.A! The shirts are cut and sewn in Haiti, a short distance from Florida...and there's a very special reason Allmade chose Haiti...and it's a BIG reason The Shack chose Allmade!

ALLMADE CHOOSES HAITI

$3 a day. That's it. That's the average DAILY wage for the average Haitian worker - a worker trying to support a family of eight! As you can imagine, it's a wage that makes it almost impossible to afford even the most basic of needs. Allmade believes in giving people a hand up, so they have partnered with the Global Orphan Project to produce these great quality shirts, and at the same time, fighting generational poverty in Haiti. LIFE, the Haitian facility where Allmade shirts are produced, is among a number of ventures the GO Project has developed to create dignified work that keeps families together. They pay workers 3-4x the going rate for similar jobs in the area, an amount carefully calculated to meet the basic needs of a Haitian household. (Courtesy of Allmade)

SHACKERS FOR ALLMADE

Already, many of our clients are catching our vision for supporting a better tee! If you're in the market for a premium triblend t-shirt, we encourage you to consider Allmade as your go-to brand! Hey, you're already buying premium soft tees, so you might as well be helping the environment and Haitian families while you're at it! Ready to start a project today? Great! We're looking for partners who want to help us change lives one t-shirt at a time!